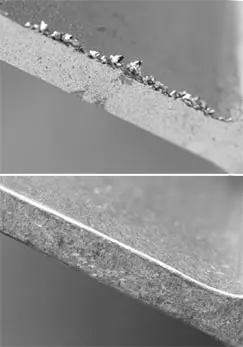

The deburring process is commonly used to remove any unwanted material attached to a piece of work after the manufacturing process. A burr may consist of a sharp, raised edge or a small piece of metal attached to the work. Manual deburring is a commonly used method in said industry. This is a flexible process as it allows for instant inspection. It is also extremely cost effective. However, there are some down sides to this method. Many manual deburring practitioners have often complained of RSI. This condition is caused by repetitive tasks or forceful excursions. Symptoms include pain, stiffness and weakness in the affected area. Those who carry out the deburring process have also been known to complain of ‘white finger’. This condition is caused by changes is sensory perception. White Finger can lead to permanent numbness in the fingers and muscle weakness. Other common methods of deburring include Electrochemical deburring, thermal energy deburring and cryogenic deburring. However, these methods are extremely costly and time consuming.

Here at PDJ Vibro we specialise in vibratory deburring. This method of burr removal is both consistently provides brilliant results and is also extremely cost effective. Vibratory deburring machines allow the operator to deburr large amounts of items in a short period of time with minimal effort. The items are vibrated in a large tub along with specifically shaped media and liquid compound. This effectively removes the burrs. This process is performed in an open tub; this allows the operator to easily observe the items inside as well as the progress being made.

Here at PDJ Vibro we strive to provide each and every customer with the perfect machine to suit their individual needs.

View the range of new deburring machines from PDJ Vibro Ltd »