Vibratory Trough Finishing Machines

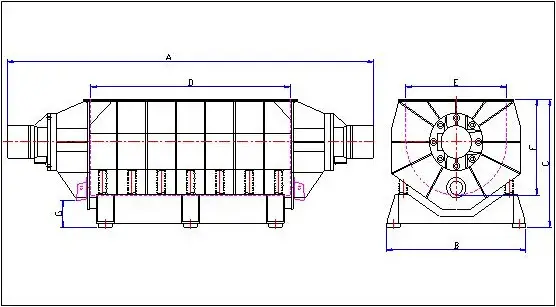

PDJ Vibro Rectangular Trough Vibrators are designed to process long components and delicate components where part on part damage is likely (chamber can be sectioned with divider plates).

- High abrasive efficiency is always combined with a good surface finishing

- Specially designed heavy-duty electric vibration motor

- Continuously adjustable vibration control

- High durable hot-poured polyurethane lining

- EVT-130 model is available with 3000 rpm vibrator motor for ball burnishing

- Machines are available with optional divider devices

Optional features include:

- PLC Controls.

- Variable speed control.

- Acoustic suppression covers.

- Chemical additive dosing.

- Effluent control.

EVT / EVT-R Technical Details

EVT

EVT-R

| Tip Type | Type A | Type C | Type D | Speed | Gross Volume ltrs | Power kW | Voltage / Frequency AC-V/Hz 3 phase | Weight kg | A mm | B mm | C mm | D mm | E mm | F mm | G mm | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|  |  | 1500 rpm | 3000 rpm | ||||||||||||

| EVT-20 | * | * | 20 | 0.55 | 400 / 50 (*) | 90 | 785 | 385 | 600 | 520 | 165 | 210 | 390 | |||

| EVT-50 | * | * | 50 | 2.2 | 400 / 50 (*) | 300 | 960 | 535 | 1140 | 750 | 255 | 325 | 760 | |||

| EVT-80 | * | * | 80 | 0.75 | 400 / 50 (*) | 110 | 1055 | 646 | 940 | 850 | 275 | 345 | 600 | |||

| EVT-130 | * | * | 130 | 1.1 | 400 / 50 (*) | 330 | 1160 | 620 | 930 | 960 | 345 | 410 | 480 | |||

| EVT-145 | * | * | 145 | 1.1 | 400 / 50 (*) | 440 | 1300 | 620 | 930 | 1100 | 345 | 410 | 480 | |||

| EVT-170 | * | * | 170 | 1.1 | 400 / 50 (*) | 470 | 1500 | 620 | 930 | 1300 | 345 | 410 | 480 | |||

| EVT-250 | * | * | 250 | 2.2 | 400 / 50 (*) | 600 | 1785 | 775 | 1190 | 1500 | 390 | 450 | 665 | |||

| EVT-R 320 | * | * | * | 320 | 2.2 | 400 / 50 (*) | 770 | 1445 | 800 | 1160 | 1220 | 510 | 550 | 555 | ||

| EVT-R 370 | * | * | 370 | 3 | 400 / 50 (*) | 790 | 1535 | 1050 | 1200 | 1300 | 590 | 590 | 500 | |||

| EVT-380 | * | * | 380 | 3 | 400 / 50 (*) | 850 | 1715 | 800 | 1160 | 1520 | 510 | 550 | 555 | |||

| EVT-400 | * | * | 400 | 4 | 400 / 50 (*) | 950 | 2200 | 800 | 1170 | 2000 | 400 | 500 | 600 | |||

| EVT-420 | * | * | 420 | 3 | 400 / 50 (*) | 990 | 1925 | 800 | 110 | 1700 | 510 | 550 | 600 | |||

| EVT-475 | * | * | 475 | 4 | 400 / 50 (*) | 950 | 1445 | 914 | 1210 | 1220 | 610 | 610 | 545 | |||

| EVT-500 | * | * | 500 | 5.5 | 400 / 50 (*) | 1080 | 1750 | 914 | 1210 | 1525 | 610 | 610 | 545 | |||

| EVT-R 600 | * | * | * | 600 | 5.5 | 400 / 50 (*) | 1270 | 2165 | 906 | 1210 | 1925 | 600 | 585 | 575 | ||

| EVT-800 | * | * | 840 | 5.5 | 400 / 50 (*) | 1600 | 1745 | 1034 | 1530 | 1500 | 750 | 840 | 625 | |||

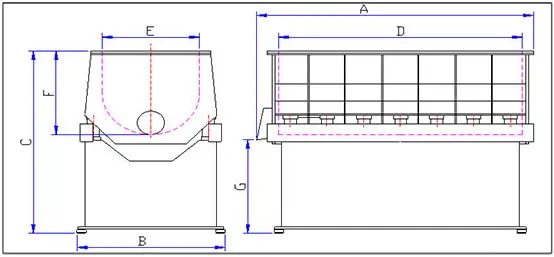

BPT models is available with 3000 rpm vibrator motor for ball burnishing.

| Tip Type | Type A | Type B | Type C | Speed | Gross Volume ltrs | Power kW | Voltage / Frequency AC-V/Hz 3 phase | Weight kg | A mm | B mm | C mm | D mm | E mm | F mm | G mm | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|  |  | 1500 rpm | 3000 rpm | ||||||||||||

| BPT-80 | * | * | 80 | 2x1.5 | 400 / 50 (*) | 630 | 1990 | 770 | 840 | 850 | 275 | 345 | - | |||

| BPT-100 | * | * | 100 | 2x1.1 | 400 / 50 (*) | 500 | 2600 | 515 | 890 | 1500 | 255 | 325 | - | |||

| BPT-130 | * | * | 130 | 2x2.2 | 400 / 50 (*) | 660 | 2200 | 760 | 1095 | 960 | 345 | 410 | - | |||

| BPT-250 | * | * | 250 | 2x5.5 | 400 / 50 (*) | 1425 | 2925 | 700 | 1010 | 1500 | 390 | 450 | - | |||

| BPT-320 | * | * | 320 | 2x5.5 | 400 / 50 (*) | 1800 | 2950 | 1100 | 1170 | 1230 | 510 | 550 | - | |||

| BPT-700 | * | * | 700 | 2x7.5 | 400 / 50 (*) | 2370 | 2650 | 1190 | 1360 | 1100 | 800 | 850 | 470 | |||

| BPT-1000 | * | 1000 | 2x5.5 | 400 / 50 (*) | 2150 | 3415 | 1170 | 1255 | 1830 | 760 | 810 | 270 | ||||

| BPT-1100 | * | 1100 | 2x7.5 | 400 / 50 (*) | 2740 | 3810 | 1170 | 1400 | 2135 | 760 | 760 | 390 | ||||

| BPT-2200 | * | 2200 | 2x11 | 400 / 50 (*) | 3100 | 4300 | 1445 | 1500 | 2200 | 1100 | 990 | 350 | ||||

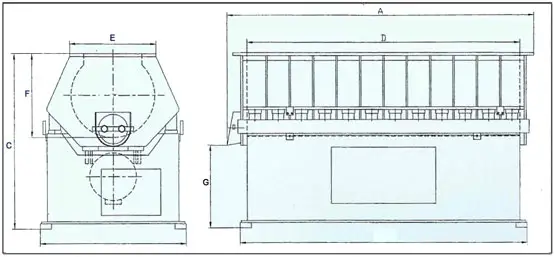

Economy Range

Rectangle Vibratory Finishing Machine T-85 / T-184

- 1270mm round discharge door, with discharge trough

- Heavy gauge steel construction coated with rust-preventative enamel

- Sound reduction cover and anchor bolts

- Polyurethane liner made from the finest quality material available and oven cured

- Optional fluid circulation system including pump, fluid container, all necessary hoses and fittings

- Dividers available for both machines

| Inside Tank Dimensions | Power HP / kW | Voltage/ Frequency AC - V/Hz | Weight kg | |||

| Length mm | Depth mm | Height mm | ||||

| T-85 | 787 | 330 | 343 | 1 / 0.75 | Single phase 110/60 220/60 | 181 |

| T-184 | 889 | 476 | 457 | 3 / 2.24 | Three Phase 230/50 440/50 | 318 |