This article discusses some important differences that the circular bowl and rectangular trough vibratory finishing machines have from one another. Each machine has a very special job in the finishing process, and knowing the subtle differences will be of great help in your choice of equipment for what you need.

Vibratory Finishing Machines With Round Bowls

Some vibratory finishing machines come with a round bowl design. This is effective for small to medium-sized parts; for example, a round vibratory bowl of 250 litres can hold many different parts. Commonly we stock up to 800 litres in order to process large-size parts, sizes up to 6000 litres have been made to order.

In a vibratory bowl, parts and materials move together in the space. The movement oscillates within the space and rotates around the bowl like a corkscrew. This process helps to keep parts apart from each other, especially if they have a similar drag factor, lowering the chance of damage.

Vibratory Trough Finishing Machines

If you’re dealing with very large components and are concerned about them touching and potentially damaging each other, a rectangular trough vibratory finishing machine is a better option. These machines allow the insertion of divider plates, or even multiple divider plates, to keep the parts separate. Without these dividers, parts can migrate to the end of the trough and cause 'chatter'.

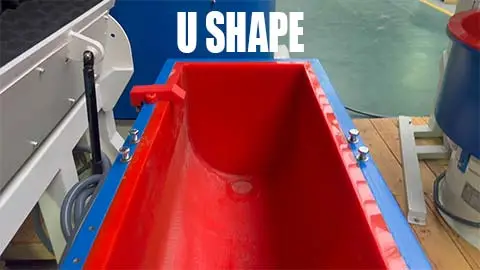

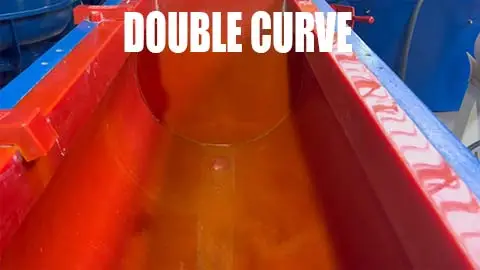

It’s important to consider the shape of the trough when choosing your machine. The most common type is the U-shaped section, but large pieces can sometimes develop chatter marks if the media gets stuck between the part and the side wall. If this is a concern, we recommend considering a trough machine with a double curve. This design tends to eliminate such problems, but we would always advise conducting trials first to ensure the best results.

Chatter refers to unwanted vibrations or oscillations in the workpiece or media during the finishing process. These oscillations can result in irregular or inconsistent contact between the media and the parts, leading to an uneven surface finish.

Vibratory Finishing Bowls And Troughs

Our showroom holds over 120 vibratory finishing machines. From the moment you contact us you will receive excellent care and technical advice on the best machine for your component finishing.

Get Expert Advice

We invite you to visit us and meet our experts. If you can’t bring your components in person, you’re welcome to send them to us for sample processing. If you’d like to learn more, give Paul or Adam a call on 01908 648757. We’d love to help you find the best solution for your finishing needs.