One of the UK’s leading specialists in 3D printing – Central London based, Digits2Widgets – has enhanced its range of surface finishing services with the recent installation of a vibratory finishing machine from PDJ Vibro Ltd. The new machine is dedicated to the high quality polishing of Nylon SLS parts and produces a very smooth, ivory-like finish.

One of the UK’s leading specialists in 3D printing – Central London based, Digits2Widgets – has enhanced its range of surface finishing services with the recent installation of a vibratory finishing machine from PDJ Vibro Ltd. The new machine is dedicated to the high quality polishing of Nylon SLS parts and produces a very smooth, ivory-like finish.

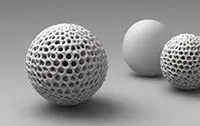

Major manufacturers have been using 3D printing for decades. Originally called “rapid prototyping”, it has become an essential production tool, enabling designers to quickly and easily create a sample product, which can then be tested, tweaked and re-printed, all within a matter of days. 3D printing methods are capable of producing complex and intricate forms that cannot be made any other way.

The Digits2Widgets team has more than 10 years’ experience of working with digitisation and 3D printing technologies and processes, and has developed a close understanding of the digital world – in three dimensions – and how to successfully extrapolate this into the physical world using the most advanced 3D printing technologies.

“The introduction of the PDJ machine was initiated by the needs of a potential customer with a large scale production project, who enquired as to whether we could vibratory finish our Nylon SLS 3D printed parts, as they had seen samples of this from an alternative 3D printing facility,” explains Digits2Widgets Design Director, Jonathan Rowley.

“Eager to be able to work with this customer, we investigated the process through PDJ Vibro and following the processing of samples, decided that the results were sufficiently impressive to invest in a machine for ourselves. As a result we have been working with this client, who has recently released their vibro-finished 3D printed product onto the market. A subsequent volume enquiry was received as a result of us being able to refine the finish of the nylon SLS and we hope to be securing a production contract for this project soon. Now we have the machine we are also able to offer this particular finishing service to other customers where appropriate.”

The PDJ Vibro ‘TBT-80’ vibratory bowl machine is used solely for processing Nylon SLS components, so there is no risk of cross contamination of materials that can lead to dirty parts. “Our Nylon parts go in white and come out white,” says Jonathan Rowley. “This is very appealing to our clients, who can use this in order to apply a polished and ‘finished’ appearance to their Nylon SLS production parts, ready for market.”

In PDJ Vibro vibratory finishing machines, the finishing media oscillates and rotates, creating a gentle, directional scrolling action. Both plastics and metallic parts can be handled. The process, which can include chemical additive combinations, can be used to produce a wide variety of finishes and surface effects. In addition to high quality finishing, these include simple deburring, edge-breaking, degreasing, radiusing, “superfinishing” to 0.03 ra and shot-peening.