Post-processing of SLS (Selective Laser Sintering) 3D printed parts is essential to achieve a better surface finish. Vibratory finishing is a technique that can be employed to enhance the surface quality of SLS printed components. Let's delve into how vibratory finishing can improve the surface finish of SLS 3D printed parts.

Vibratory finishing, similar to its application on other 3D printed components, involves placing SLS parts into a vibratory finishing machine along with abrasive media and a liquid compound. The machine's vibrations cause the media and vibratory finishing compound to interact with the parts, resulting in various surface improvements.

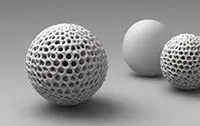

IMAGES: 3d printed parts are often too rough and with spectacle frames a silky finish is achieved with a specialist PDJ Vibro additive-manufactured formula.

Here are the key advantages of using vibratory finishing for post-processing SLS 3D printed parts:

Surface Smoothing: Vibratory finishing effectively reduces the roughness of SLS printed parts' surfaces. The abrasive media, such as ceramic, plastic, or metal, rubs against the parts, diminishing the high points and creating a smoother surface finish.

Minimization of Layer Lines: SLS 3D printed parts often exhibit visible layer lines due to the layer-by-layer sintering process. Vibratory finishing can help reduce or eliminate these lines by gently abrading the surface, resulting in a more uniform appearance.

Deburring and Edge Radiusing: SLS parts may have sharp edges and burrs as a result of the printing process. Vibratory finishing can effectively remove these imperfections by rounding edges and eliminating burrs, resulting in safer and visually appealing components.

Polishing and Surface Refinement: Vibratory finishing is also capable of achieving a polished surface finish on SLS 3D printed parts. By selecting appropriate polishing media and compounds, it is possible to enhance the appearance and create a smoother, more refined surface.

Stress Relief: Vibratory finishing aids in stress relief for SLS printed parts. The mechanical agitation helps reduce internal stresses generated during the sintering process, leading to improved dimensional stability and enhanced mechanical properties of the components.

To obtain the best results with vibratory finishing for SLS parts, it is important to consider the following factors:

Media Selection: Different types of media offer varying levels of abrasiveness and surface refinement. The media should be chosen based on the desired surface finish and the material of the SLS printed parts.

Compound Selection: Liquid compounds can be added to the vibratory finishing process to enhance cleaning, polishing, or rust inhibition properties. Selecting the appropriate compound can further improve the surface finish and provide protection for the parts.

Process Parameters: Optimizing the vibratory finishing process parameters, such as vibration speed, amplitude, and cycle time, is crucial for achieving the desired surface finish on SLS printed parts. Experimentation and testing may be necessary to determine the optimal parameters.

It's important to note that while vibratory finishing can significantly enhance the surface finish of SLS 3D printed parts, its applicability may vary depending on factors such as part geometry, material composition, and specific requirements. However, when implemented effectively, vibratory finishing can greatly enhance the surface quality and overall appeal of SLS 3D printed parts.